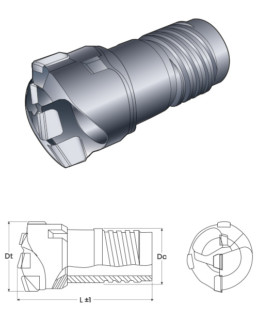

Destructing Heads.

Easy to use

- No pre-setting

- No need for tool room service

Excellent hole straightness and surface finish

Customer specified diameter

- Finish ground within 0,01mm increments

Reliable performance

- Robust design enables high feed rates

- Sintered insert geometries ensure consistant troublefree chip control in most materials

Wide application area

- Optimized grade- and geometry combinations for most workpiece materials

Easy to use and handle

- Fixed insert seats: no pre-setting and no need for tool room service

- Few spare parts: low inventory costs

Excellent hole straightness and surface finish

Reliable performance

- Robust design enables high feed rates and productivity

- Wear resistant drill body manufactured in hardened steel

- Customer specified diameters

- Close tolerances

Productivity in a wide application range

- Modern grade and geometry program cover most workpiece materials

- Few inserts and support pad sizes cover the whole diameter range

- Excellent chip control in both low and high feeds

Easy to use and handle

- Possibility of adjustment

- Few spare parts

Excellent hole straightness and surface finish

Two types of insert cartridges, strong and secure

Possibility to equip the head with 2 different types of cartridges.

- Designed to protect the head from damage

- Easy to change

- Good economy

Adjustable peripheral cartridge

- Easier radial setting

- Short setting time

- Improved precision

Machining economy

- Grade and geometry program cover most workpiece materials

- Few inserts cover the whole diameter range

- High feeds

Easy to use and handle

- Possibility of adjustment

- Few spare parts

Excellent hole straightness and surface finish

Insert cartridges strong and secure

Designed to protect the head from damage.

- Easy to change

- Good economy

Adjustable peripheral cartridge

- Easier radial setting

- Short setting time

- Improved precision

Machining economy

- Grade and geometry program cover most workpiece materials

- Few inserts cover the whole diameter range

- High feeds

CONTACT US FOR THE CATALOGUE